Deicing using the example of EDDM

Introduction

Aircraft are becoming more and more sophisticated and complex, there are more and more plugins that are close to reality and there is more and more interest in implementing real procedures - that's why we want to deal with the topic of "deicing" here.

First of all, this is more of an "eye opener" to shed light on this topic, which is actually very interesting but has been unfairly underappreciated. As we have to go into more detail here, the text will be a little longer.

General

What is deicing and why is it important?

Frost, snow, ice and other contamination have a considerable influence on the aerodynamics of an aircraft. Just a few millimetres of contamination / ice on the upper surface of the wing can significantly influence and even disrupt the airflow and thus impact flight characteristics. Many aviation disasters are related to icing (just search for "aviation incidents / crashes deicing" on Google).

Deicing can be done mechanically (e.g. using a broom / shovel to remove snow from the wing surface) and chemically (i.e. with deicing fluid using deicing vehicles).

When do you de-ice? Only in snowy conditions, right?

There are many reasons that make deicing necessary. Very often deicing is needed even though it is not snowing at all, possibly even when the sun is shining. Here is an example: You arrive in Munich after a 6-hour flight and still have cold fuel left in the wing tanks, which are at -40°C or colder. At the turnaround you refuel for the next leg of your flight, it is +6°C in Munich and cloudy, sometimes the sun is even shining. What happens now? The warm, new fuel enters the tanks, hits the still very cold wing and a layer of clear ice forms on the top of the wing, the so-called "cold soaked wing effect" has occurred. Since, as mentioned above, contamination of the aircraft parts is not at all compatible with the aerodynamics of the aircraft, deicing can be necessary in sunny/cloudy conditions and at temperatures way above 0°C.

Who decides when to de-ice? Who actually de-ices? Who has the final say?

First of all, the PIC (Pilot in Command). They are responsible for the safety of the flight and so they decide whether to de-ice or not. Whether the wing is completely free of contamination and looks brand new and they still want to de-ice is up to them. Even if, as has unfortunately happened often enough, a rolling igloo taxis towards the runway, deicing is still the pilot's (...or the airline's financial situation...) decision.

However, as soon as an aircraft has registered for deicing, deicing is carried out by the respective airport operator or the handling agents. They alone then decide WHAT is de-iced on the aircraft and HOW. They are the last ones who inspect the aircraft and therefore assume liability / responsibility. They act according to the "CAC - clean aircraft concept", i.e. the aircraft must have been freed of any build-up and contamination after deicing. So even if there are only a few small snow residues on the fuselage of the aircraft, the entire fuselage (or at least parts of it) is de-iced, even if the PIC decides against it. He has no authority whatsoever (with the exception of technical backgrounds for special aircraft types / restrictions).

How is deicing carried out (using Munich EDDM as an example)?

A distinction is made between 1-step deicing and 2-step deicing.

In 1-step deicing, a mixture of type 1 fluid and very hot water at almost 80°C (type 1 is always orange in color) is applied to the aircraft, contamination is removed and at the same time a protective layer is applied to prevent re-icing.

In 2-step deicing, the contamination is first removed from the aircraft with type 1 and then "anti-iced" or protected in the 2nd step with type 4 fluid (cold, not heated, green in color and rather viscous).

What is Holdover time?

The holdover time, or HOT for short, is the period of time during which the aircraft is protected from re-icing. Depending on the type and method of deicing, the weather conditions, the type of aircraft (classically mainly aluminum, e.g. B737, or increasingly composite materials, e.g. B787), the deicing process used, etc., this can range from just a few minutes to several hours. Once the HOT has expired, there is no longer any reliable protection against contamination. Every (sensible) pilot will therefore want to de-ice again. However, the pilots themselves have leeway here and can still take off at their own discretion.

Where is deicing carried out?

In Munich, deicing takes place directly on the deicing pads/areas, which are located directly at the holding points in front of the respective runways. This concept makes Munich almost unique in the world (more on why this is so ingenious and why it is mentioned separately in a moment).

There are typically 3 deicing pads per active runway. In other words, for 08 operations, the intersections A1/A2/A3 at 08L are/can be used for deicing, and B1/B2/B3 at 08R. The holding points are simultaneously the deicing pads (08L A1 becomes deicing pad 1, A2 becomes deicing pad 2 etc. ... ) The same is true for 26 operations: Here there are A13/A14/A15 in the north which become the deicing pads DA13/DA14/DA15. In the south, simultaneously B13/B14/B15 etc turn deicing pads. Incidentally, you will find these on the ground charts as "DA14" = DeicingArea 14.

Propeller machines without prop brake are deiced in position, i.e. they receive apron deicing.

Why is deicing directly at the runway so efficient?

We learned above that the holdover time starts as soon as the deicing procedure begins. This is where the clock starts ticking. At airports with so-called apron deicing procedures, the clock starts ticking with the deicing procedure in the aircraft’s parking position. Then, the pilot still has to push, may additionally suffer a delay due to taxiing traffic and then we are looking at 10-20 minutes taxi time to the runway and possibly even more waiting time at the holding point. This time is wasted unnecessarily and minimizes our HOT.

The advantage of remote deicing (i.e. at the holding points) is that you can taxi to the CAT2/3 holding point immediately after deicing, do the engine runup (should be done after deicing) and take off directly. This minimizes time losses and the chance of having to de-ice again due to expired HOT is very small.

Another advantage (even if completely unnecessary on VATSIM)

In Munich, there are collecting tanks underneath ALL deicing pads. The deicing fluid / snow drains into these collecting tanks through small grooves on the deicing pad. The deicing fluid is collected, treated and can be reused, and up to 70% of deicing fluid can be completely reused. This saves a lot of money, protects the environment and the waste heat generated is used to heat an entire terminal. Pretty ingenious!

I want to de-ice! Where do I have to register?

In reality, there are many different ways to do this. Normally, pilots call in at least 20 minutes before TSAT (Target Startup Approval Time) on 121.990 Mhz (callsign "Munich Deicing Coordinator") and register there for deicing. The coordinator sees all information about the flight on their system and confirms the registration by radio. Depending on the airline, it is also possible to register for deicing via ACARS, but we are not (yet?) able to do this on VATSIM. Alternatively, you can call Tower, Ground, Delivery, Handling Agents etc. directly.

So how is deicing handled on VATSIM?

You call in at Delivery or the lowest position responsible for you and register for deicing in advance.

| Station | Phraseologie |

| Pilot | München Delivery, DLH4YA, require deicing before departure. |

| ATC | DLH4YA, request confirmed, you are in the sequence for deicing. |

After registering, you can push and taxi as normal and during the handover from apron to tower the tower will guide you directly to your designated deicing pad.

| Station | Phraseologie |

| Pilot | Tower Servus, DLH4YA, Entry S8 for deicing. |

| ATC | DLH4YA, servus, taxi deicing area B15 via S, on second radio contact decing crew on XXX,XXX Mhz, report deicing completed. |

(If, out of boredom, an ATC were to join the frequency and simulate the deicing crew for fun)

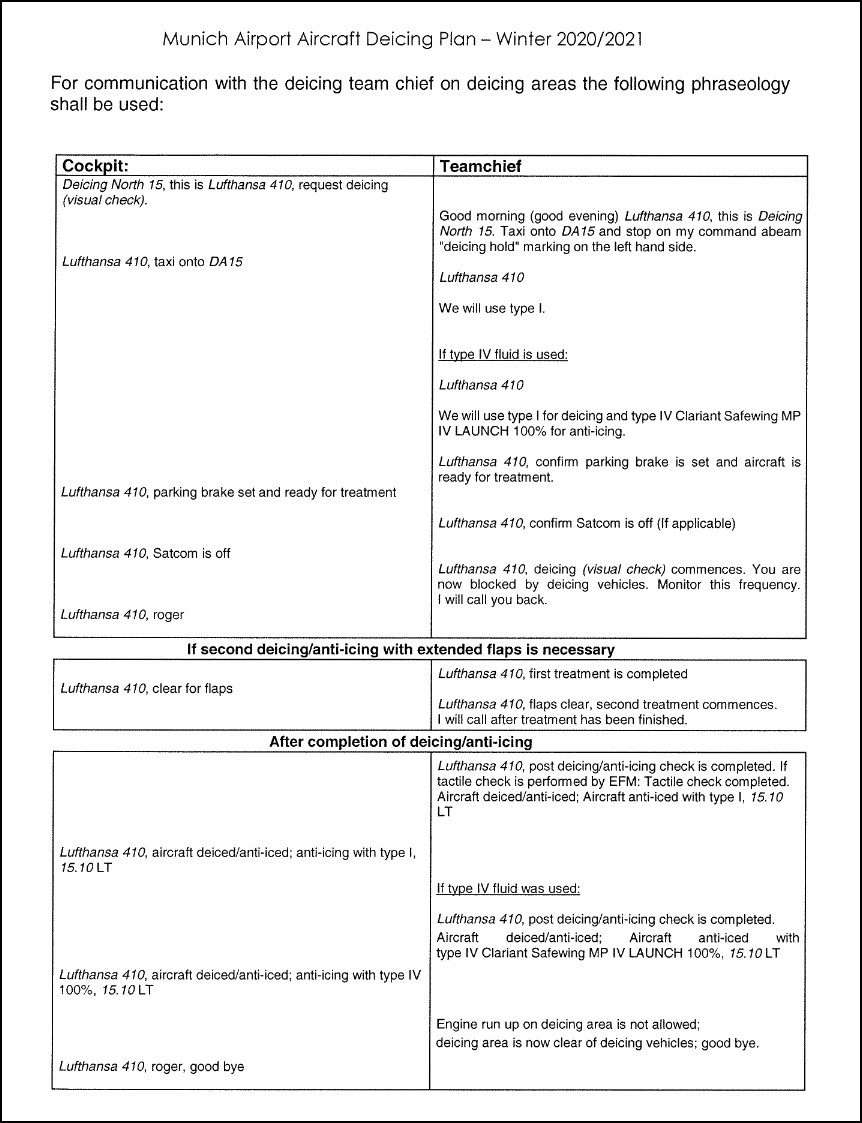

Everything else is simply improvised and simulated, that's all that's technically possible at the moment ;-) Here is an excerpt from the official document on deicing at Munich Airport, including the course of the conversation:

Crash course on METAR vs. HoldoverTime

Using the following example, I would like to briefly and roughly outline how to select the HOT / deicing variation from the tables using the current METAR information. I'll try to keep this extra short, so I won't cover every footnote or all the details:

We have the following METAR:

1820Z EDDM 26015KT 2000 -SN BKN006 OVC020 M02/M04

In short (and only very roughly!), weather report from 18:20 Zulu (i.e. in the evening), from Munich, wind from 260 degrees at 15 knots, 2000m visibility RVR, light snowfall, cloud cover at lower limit 600 ft, closed cloud cover lower limit 2000 ft, temperature -2°C, dew point -4°C.

Now I already know we don't have "active frost" alone where we can only deice / anti-ice 1 step with type 1, but we have evening / darkness, low visibility due to snowfall and sub-zero temperatures.

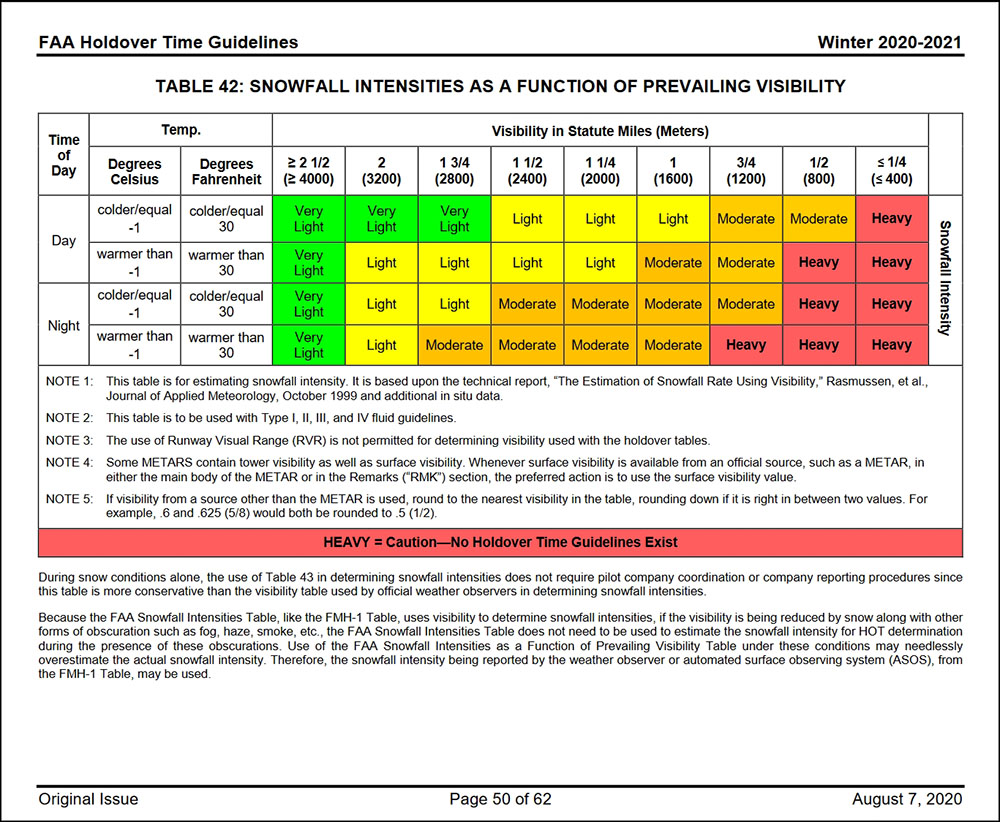

Since we only have RVR values (in real life we use the MOR meteorological observation range), we go directly to Table 42: SNOWFALL INTENSITIES AS A FUNCTION OF PREVAILING VISIBILITY. We know it is evening, so we go to the left column under "Night". We also know it is currently -2 degrees, so we go to the "colder/equal -1" column.

Now we take the reported visibility of 2000 m and look at the top of the column where we have to position ourselves. In our case at 1 1/4 (2000). Well, one finger to the left, one finger from above, put the two together and we end up with the value "MODERATE". Quite simple, isn't it?

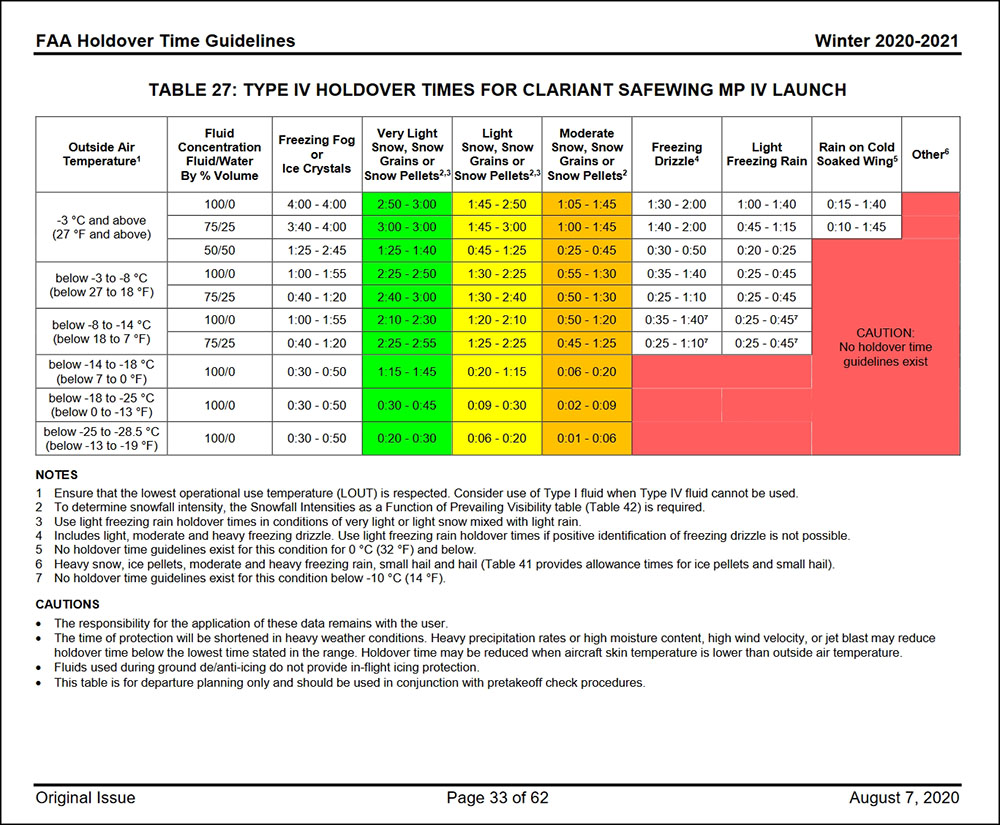

With this "MODERATE" value in mind, we now go over to Table 27: Type IV HOLDOVER TIMES FOR CLARIANT SAFEWING MP IV LAUNCH (This is the deicing fluid type 4 with a concentration of 100%, which the deicing coordinator told us is what they used).

Now we continue as before: We know in the left column at "Outside Air Temperature" we have 2°C, ergo we are at "-3°C and above". We also know that the concentration is 100% type 4, so we go to "100/0" in the column.

We have previously picked out the visibility and the respective value, which was "MODERATE" and slide into the respective column to "MODERATE SNOW; SNOW GRAINS OR SNOW PELLETS"..... and get a value of 1:05 - 1:45. This means that as soon as the anticing starts, i.e. the first contact with type 4 on the aircraft, we now have a holdover time of between 1h:05 min and 1h:45 min. This will get you out of ATC pretty reliably and you still have a good time buffer. So it wasn't that difficult after all ;-)

I have attached the tables, if you want to read a bit yourself just search for the "FAA2020-2021 Holdover Tables".

This should give you a rough insight into the world of de-icing, why it is so important, what is behind it, how it roughly works and what approximate processes are behind it. Xplane, FSLabs and the Majestic Dash Q400 already simulate icing, GSX and Co. allow you to de-ice yourself and the developers of aircraft are picking up this topic more and more.

We (RG Munich) are always happy to answer any queries, suggestions, technical questions or discussions! This thread may be expanded if necessary. Spelling mistakes and other errors can be collected and exchanged for an ice cream.

Epilog

This article was created by Florian Weingartner, RG Munich, who kindly agreed to transfer it to the Wiki.